3D printing is a manufacturing method invented in the 1980s. The technique has come a long way and become the center of the additive manufacturing market. 3D printing is applied in a wide range of industries like the health, food, architecture, education, construction, and automotive industry. The applications of this manufacturing technique keep increasing by the day as the technology is enhanced. Commercial 3D printers are used to manufacture products at an industrial level. This write-up covers 3D printing quality and the factors that affect it.

Factors affecting the 3D printing quality

Several factors can influence the quality of 3D printing. Below are a few:

1. The thickness of the layer

The thickness of the layer is connected to the settings of the slicer. These settings are typically obtained from the code. Note that the type of printer you are using may also influence the thickness of the layers. Some 3D printing technologies also cannot withstand certain layer thicknesses. Naturally, the thinner the layers, the smoother the walls of the prints will come out. Therefore, the thinner the layers, the better the quality, and vice versa.

2. Material quality

The mechanical properties of the material used in 3D printing can also significantly impact the quality of the process and its outcome. Naturally, poor materials will result in inferior 3D printing and vice versa. This is primarily because of the impact of the material on the strength and hardness of the printed products. Note that the quality of the material can be measured through its diameter deviation. The larger the deviation, the more the issues with the quality. It is worth mentioning that the quality of the material chosen depends on the product being manufactured.

3. The temperature

In 3D printing, heat is a standard element. Therefore, it is natural that temperature control is one of the elements that influence the quality of the material. It is paramount to mention that the temperature is directly related to the slicer set-up. The temperature is usually configured differently depending on the type of 3D printing material. Therefore, to ensure impeccable 3D printing quality, you must ensure that the temperature is suitable for the process and the type of material. It should not overwhelm or underwhelm the process. Using proper temperatures will ensure that your 3D printing is successful and the outcome is perfection.

4. Retraction

Retraction refers to when the extruder travels some distance without extruding the material. The perfect material retraction will significantly affect the quality of the finished product. It does this by preventing the formation of small clods of material on the material perimeters. In 3D printing, you have the freedom to experiment with retraction to ensure you get the perfect levels for the benefit of the outcome.

Conclusion

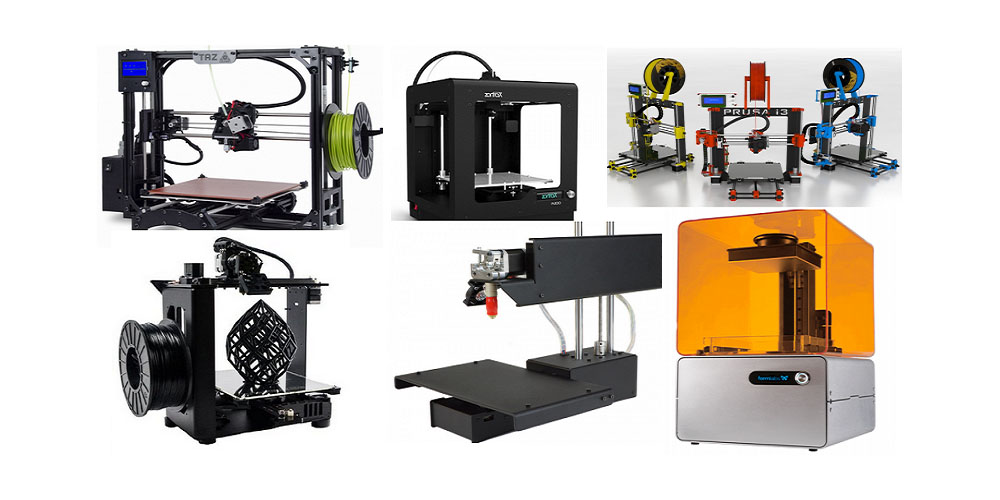

In addition to the elements listed above, several other factors can influence the quality of the process. The type of 3D printer and how it works is one of these factors. The market features a wide range of 3D printer types. They all have the same working principle. However, they all have their strengths and shortcomings. The shortcomings affect the quality of the process and its outcomes.