CNC machining is a process of manufacturing that employs the use of computer programs to manage the movement of tools and machines in factories. In the process, computer software is pre-programmed in such a way that it controls all the movements of tools and machines used in the manufacture of products. This computer software can be used to control all types of machines from the least to the most complex ones.

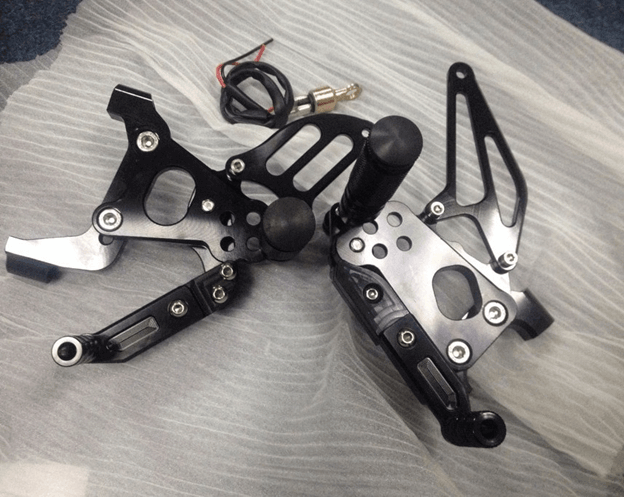

This is one of the easiest and most efficient methods of manufacturing as it produces parts without any flaws. This very process is applied in a variety of industries, including the motorcycle manufacturing sector. In this sector, CNC machining is primarily used in the manufacture of custom motorcycle parts. CNC machining for motorcycle parts has a lot of benefits, which we will be discussing in this write-up.

Advantages of using CNC machining in the manufacture of motorcycle parts

- Accuracy

One of the major benefits of CNC machining as used in the manufacture of parts is that it is very accurate. The accuracy feature is supported by the fact that the process involves computers and not human labor. Computers are autonomous, which means the amount of accuracy you can accomplish using a computer to control machines in the factory cannot be achieved if humans had the control.

- 100% similarity index

One feature that stands out about CNC parts is the fact that they are all the same. This is especially the case if the same machine manufactures them. These machines are programmed with a design that can be used to manufacture thousands of parts at a time without any difference. This is the perfect way for motorcycle companies to make parts that are unique from other brands yet similar in all their products.

- Rate of production

CNC machines can be used continuously for a very long time. The same cannot be said about other types of machines used in production. However, this can only be achieved if the machines are manufactured properly and when they are maintained occasionally. With proper maintenance, it is possible to keep them running for a whole year. For this reason, the rate of manufacturing in CNC machining is quite impressive.

- Cost

CNC parts are more cost-efficient than the latter. If you are a bike junky, you know that replacing parts is not cheap. This is not the case of CNC motorcycle parts. CNC parts are cost-efficient because they do not take a long time in production; therefore, there are fewer labor hours and costs of production.

- Durability

Motorcycles are prone to a lot of harsh conditions that may lead to wear and tear. CNC parts for motorcycles would be able to endure such conditions without suffering as much damage as the latter. They are, therefore, long-lasting and more efficient than the latter.

Conclusion

The best mode of manufacturing custom motorcycle parts is through CNC machining. Using a few of these parts, you can get a custom looking bike without changing all the components. CNC engine and motor parts are also a factor to consider. Other parts that you can customize using CNC machining include wheels and lights.