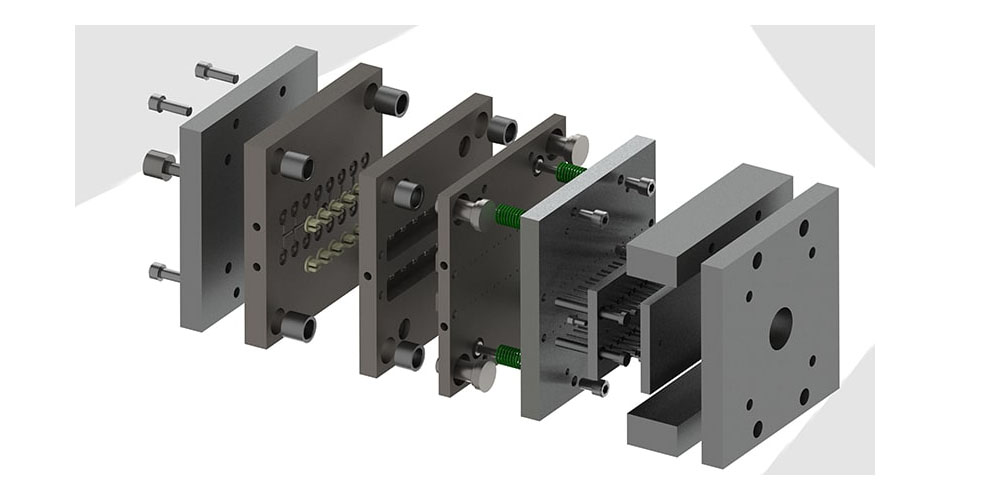

Injection-molded prototypes are produced with the same manufacturing procedures as mass production. The major difference is the processing and tooling used in the parts. Furthermore, an injection-molded prototype is not as sturdy as the final part. It is developed using softer steel or aluminum to minimize the labor used and the material costs. The main function of an injection-molded prototype is to prove that the prototype will work efficiently. Thus, the majority of injection mold prototyping costs is in tooling. Several other factors affect injection molding prototype costs. Therefore, this post will update you on the five factors that affect injection molding prototype cost.

Five Factors that affect injection molding prototype cost

1. Steel type used

Steel is essential for mold creation. There are several types of steel used in the injection molding prototype process. Example of steel used is copper, alloy, P20, and H13. Furthermore, the type of steel you use for your part depends on your specifications and use. Additionally, the mold life plays a crucial role in determining the material’s costs. That is, durable steels mean high mold life, thus high steel costs. Therefore, if you want to use good quality steel, you will need to use durable steels that will guarantee high mold machine costs. The higher the steel quality used, the more expensive the injection molding prototype cost will be.

2. Production location

The location you choose to manufacture your prototype molds plays an essential role in the overall costs. Different regions have different factors that encourage high or low manufacturing costs. Some countries like China have cheap labor that ensures lower production costs than countries with high labor costs. In addition to labor, some countries have more affordable electricity costs that also reduce production costs. Therefore, manufacturing location plays a vital role in the overall injection molding prototype costs.

3. Complexity and design of a part

Parts designs usually range from simple to complex designs. Thus, intricate parts mean complex molds. Therefore, the more complex a design is, the more expensive the injection molding prototype will be. It is because more tooling is required in intricate parts than during the production of simple parts. Furthermore, if you wish to customize your part, then the mold will also be expensive. Production of complex components may need secondary EDM processes that may be time-consuming.

4. Size of part

Sizes of parts can range from small to large. Thus, the larger a part is, the more material will be required, leading to high costs. The opposite is also true; the smaller a part is, the lower the costs. Therefore, how much your part with depends on the size you need.

5. Surface finish

The type of surface finish on a part depends on one’s specifications. Furthermore, the overall mold costs will depend on the finishing you want for your part. For example, mirror polishing and high texturing can increase the costs of injecting a molding prototype.

Conclusion

Different factors play a crucial role in the overall injection molding prototype cost. But, the essential point to note is that the type of part and your specifications of the part play a significant role in the costing.