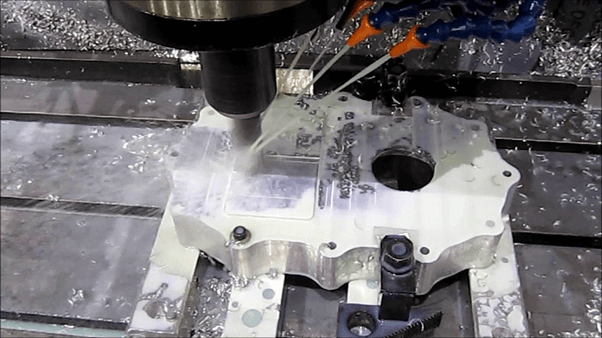

Computer numerical control machining, also known as CNC Machining (CNC milling services), refers to the automated removal of different materials from a block, like plastic or, better yet a metal resulting in a finished product. That process, also identified as subtractive manufacturing, is often controlled using a computer program and then executed via motorized machine tools. In this article, we highlight detailed information regarding CNC milling services.

So why invest in CNC machining?

At proto labs, the management offers viably quick-turn machining that works appropriately for rapid and low-volume prototyping. The stock, usually of over 30 engineering-grade thermoplastic coupled with metallic materials, can always help in making machining a perfect choice for testing the functionality of a product.

Also, they provided the hundreds of CNC machine manufacturing elements in rather less time than the actual time taken to acquire a quote from traditional machine shops; the whole process assists you in remaining ahead of schedule.

CNC Machine Milling

Milling refers to a unique machining process that utilizes different rotary cutting tools that easily move along different axes to yank out material from a given block.

A good CNC milling process utilizes 3-axis milling coupled with 5-axis indexed milling in cutting a choice of over 30 engineering-grade thermoplastics besides metals into complex shapes. The same machine and process can be used to create relatively precise elements.

Turning

Turning refers to a CNC machining process that uses some lathe material to create a detailed and functional prototype with various cylindrical features. The turning process utilizes a rod stock, rotated against the tooling to design the final products using an axial hole and a groove.

The history of CNC Machining

In the 18th century, a man started the CNC machining process. In the real sense, actually, the first turning machine that had some machine with a metallic frame was invented then. The first turning machine was introduced into the market in 1751.

The initial long series of various machines was geared towards creating a precise operation mechanically as compared to the possibly handcrafted techniques. It marked the outset of industrialization.

Around the time of the Cold War, the development of different automation systems was vividly addressed. So at that time, Parsons Works was entrusted with the responsibility of enhancing the production line for various helicopter blades. In 1952, a man by the name Richard Kegg partnered with MIT to develop a top-notch CNC milling machine. So the Cincinnati Milacron Hydrotel became the first CNC milling machine in the market. It marked the commercial outset of the technology.

The production industry relies on CNC machining to shape models and other elements. The multiple CNC machine advantages imply operator-required equipment have in several cases, been largely replaced. At the same time, the manufacturers of several types of machines in multiple sectors choose the pros of CNC machining entirely for the fabrication applications.

Final Thoughts

CNC milling services include different processes that often meet stringent client demands. You can go ahead and upload the CAD files and then gain access to instant quotes before getting your parts into a viable production in just a few minutes.