The market is packed with a wide range of printing techniques and printing equipment. One of the most popular methods is flexographic printing. The method dates as back as the late 1800s. However, it got prevalent in the early 1900s when flexo printing plates were introduced to the general market. As the name suggests, it is a highly flexible print method that involves various materials. In this post, we discuss flexographic printing features.

Significant elements of flexographic printing

Below are the top features of this printing technology;

1. Substrate

The substrate refers to a material used for conversion in the printing process. In simpler terms, the substrate is the material onto which an image or content is printed. The most common types of printing substrate are plastic films, textiles, plastic containers, and different paper varieties. Flexographic printing is popular because it allows you to print on any substrate. This means that flexo printing enables you to print on paper, plastic, foil textiles, and every type of substrate that you desire. This included direct thermal media. Regardless of the substrates used, this printing technology produces superior quality graphics.

2. Heat sensitivity

Unlike other popular printing techniques, flexo printing is not heat sensitive. This means that the method can handle any material regardless of heat sensitivity as an issue.

3. Production rate

Using flexographic printing technology also features the benefit of high speed. This benefit is all thanks to the flexographic plates. They run at hundreds of feet per minute. They also use fast-drying ink. This eliminates the need to allocate drying time for each color before the next one is printed. The production rate is also influenced by the fact that the production process is continuous. Features like the coil foils, embossing, and other significant embellishments are integrated to make the process faster. The fast production rate is why flexo printing technology is an efficient and low-cost technique for high volume runs.

4. Durability

Another critical determinant of durability is the precise color matching. Flexographic printing uses Pantone color-matching technology. The use of flexographic measuring tools and inks helps to make this possible.

5. High quality and durable labels

Labels produced by flexographic printing technology are more durable. This means that they have a longer shelf life. This is why labels exposed to harsh environments and weather elements are mostly printed with a flexographic printer.

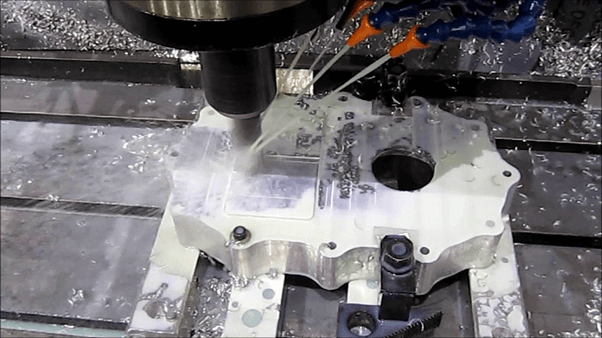

6. Expensive printing plates

Flexo printing plates are the most vital components of the flexographic printing process. While the plates help to produce high-quality products, they are also very costly. Also, note that the process involves multiple plates. Each plate prints a single color. The substrate is transferred from one plate to the other during the flexo printing process. Not only is the cost of acquiring the plates high, but it is also not an efficient method for short runs. Using the technique for short runs is more costly than other techniques.

Conclusion

Flexo printing features numerous benefits. It also features a few disadvantages. For instance, it can be costly if used for short runs. However, the benefits outweigh the drawbacks. This is the reason why, after several years, it still exists in the print market.